Tyler’s 13.8 miles of brick streets give East Texas town historic charm

Published 2:53 pm Monday, August 17, 2015

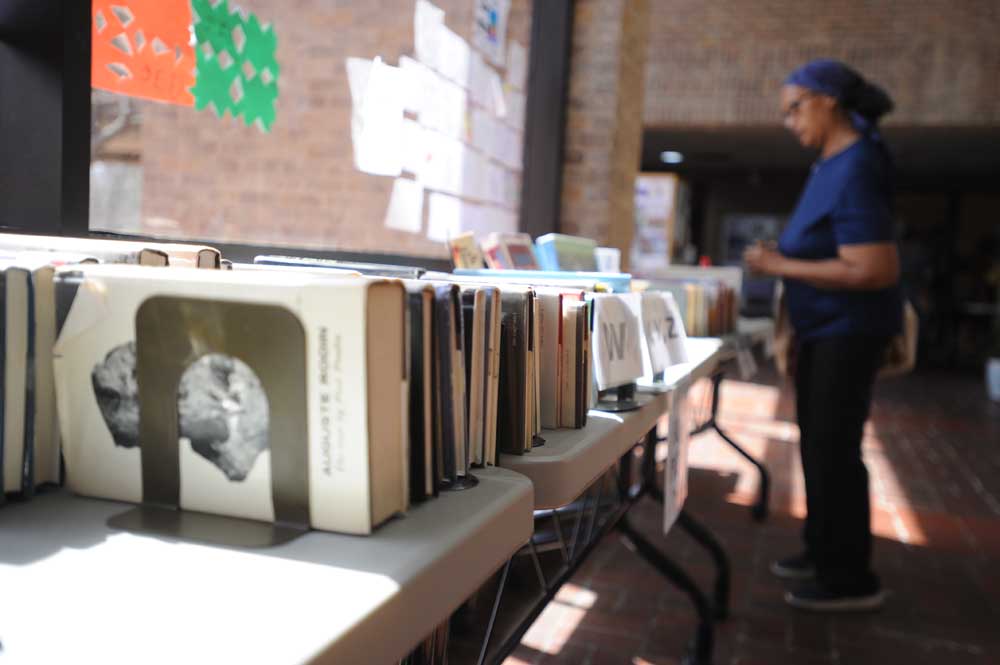

- Tyler street department worker Kevin Kennedy lays bricks at the intersection of College Ave. and Shaw Street Tuesday August 4, 2015. (photo by Sarah A. Miller/Tyler Morning Telegraph)

They’re cherished by residents and visitors to the Rose City.

The iconic brick streets that encompass almost 14 city miles were put in to help promote commerce downtown, and they still do, primarily through tourism these days.

When they were installed at the turn of the century, it was because downtown vendors complained their goods were dirty in the summer because of dust kicked up from the dirt roads. Wet roads in the winter made transporting goods from the rail lines to the stores downtown difficult, so Tyler’s brick streets – the first paved roads in the city -were installed to help promote business downtown, Tyler Streets Operations Manager Robin Smart said.

Today, the brick street district is made of roughly 12.6 million bricks and encompasses 13.8 miles in the oldest portions of Tyler.

“The brick streets are an integral part of the identity of downtown Tyler,” said Mayor Martin Heines. “Although they have different maintenance needs, they have been part of our community for a long time and will continue to add to the unique character of our downtown and historic residential areas. The brick streets are beloved by both our own residents as well as visitors from around the country.”

The first streets were constructed around 1912, according to data from the city. In 1925, Tyler voters passed a bond to construct 15 streets to add to its base of 11 already constructed.

Newspapers at the time heralded the move as “the largest public improvement project ever launched in the city of Tyler” and said the change would bring about “the beginning of ‘new Tyler.'”

Nine decades later, those streets are still structurally sound, but continuing the lost art of their maintenance is a costly endeavor for the city.

OUT OF PRODUCTION

The city’s streets are made of three different types of bricks, none of which are in production anymore.

The city relies on stockpiles of the bricks for repairs and maintenance.

The Tyler Morning Telegraph donated roughly 26,000 bricks last year that it unearthed during construction of a parking lot on Erwin Street. A street once covered the plot of land, and the city was glad to send crews to collect them, Smart said.

The modern equivalent for brick streets is called a “concrete paver,” essentially a brick made out of concrete and then dyed red, City Engineer Carter Delleney said. The city has some of those replica bricks for aesthetics downtown on Broadway Avenue.

The old-style bricks are about three-times stronger than those made now, Smart said. Concrete pavers can be broken with a hammer, while the brick in the streets takes more effort to crack, he said.

Because the bricks are a finite resource, the city has set rules on how they can be handled.

Utility companies are required to pull up the bricks individually when they make cuts into the road for infrastructure improvements, and the bricks are stacked on the side of the road for city crews to gingerly put them back in place, Smart said.

The city is working to find a company to help Tyler create a long-term maintenance plan for the streets, Delleney said.

The city has found one company in its searches that specializes in brick streets, but has not yet secured a contract.

“Essentially what (this company) produces is some formal guide to not only rate the streets, but to how to reconstruct them and get documents on cross sections and what they should look like and the best way to arrange the bricks,” Delleney said. “There’s a science to it more than throwing bricks down on the sub-base, but it’s been a slow communication process.”

MADE TO LAST

The city’s brick streets were installed between 1912 and 1947.

They were made with a 4-inch concrete base followed by a layer of sand to allow the road to give as cars pass over, Smart said.

The bricks were laid on top of the sand and hot tar was poured over the top, followed by a dusting of sand.

The tar seeped into the cracks, sealing the bricks, and over time, the black coating wore away, revealing the red underneath.

Some of the original streets have been paved with modern asphalt, but the brick structure underneath remains. The bricks are the sub-base for numerous streets in the old-town area, including the downtown portions of Broadway Avenue.

“With a brick street, you have iron ore sub-base,” Delleney said. “That is very strong. … That gives you a lot of stability, and if the base fails a little, underneath you have a rigid structure in a brick. … If the base goes bad on a brick street, it takes a while to notice.”

The city has paved over some of the original streets in high-traffic areas, but maintains a commitment to keep the rest of the system.

EXCLUSIVE CREW

The city maintains a crew of three workers who exclusively repair the brick streets, Smart said.

All of the work is done by hand.

“This is a young man’s job,” Smart said. “It’s manual labor. Most of the work is one with picks and shovels, and on your knees laying bricks.”

The city has two main reasons for brick street maintenance. The first is for utility cuts to put in new infrastructure and the other is for what the city calls “level ups,” which make sagging areas level again.

The cost of repairs varies month to month, and the funds for the repairs come out of the street department’s general budget. This year is the first for the city to maintain a cost estimate for maintaining the streets, and so far it has spent about $47,000 on repairs in 2015.

The bricks are carefully taken up, but Smart estimates about 10 percent of each brick is lost every time it is disturbed.

Each brick is laid back down, and cracked or broken bricks are replaced out of reserves, Smart said.

Crews manually lay a fresh layer of sand, place the bricks and then seal them with dyed concrete. The colored concrete is for aesthetics so the streets do not look like a patchwork quilt.

The city has its own concrete hopper so it can make small batches as needed.

Once the bricks are laid, it takes a few days for them to fully dry, Smart said.

The process is much more labor-intensive and takes longer to dry than an overlay.

COST OF HISTORY

Because of their labor-intensive nature, brick streets are expensive to maintain.

Maintaining the bricks can cost between $7 and $17 per square foot, depending on what needs to be done underneath. By comparison, a seal coat costs the city on average about 35 cents per square-foot, and an asphalt overlay costs about $1 per square-foot.

It’s hard to say how long the city’s stockpile of bricks will last.

Smart said it all depends on the number of utility cuts and infrastructure improvements that need to be done.

“It’s hard to tell,” Smart said. “We go through periods of time where we use lot of bricks, and then we go through a lot of time when we can utilize the bricks we have (in the street).”

The city makes every effort to preserve the existing bricks, but sometimes imperfections are only noticed when they are pulled up. Smart said cracked bricks are stable until removed because they are bonded in by the tar. Others are so well bonded that they are broken while trying to pull them out.

“As far as a how long stockpile (will last), that will be determined by how many utility cuts or infrastructure improvements (are made) in the brick streets,” Smart said, adding every time they are disturbed a percentage of the bricks are lost.

Twitter: @TMTFaith